2025 Year in Review - What are we cooking up for 2026 and SHOT: Catch up on everything from the live session, now available on-demand. Watch the Replay

Inventory Management for Retail, Wholesale, and Manufacturing

Coreware’s inventory management platform is built to handle the complex needs of modern businesses. From tracking inventory across multiple locations to managing serialized items, kits, and assemblies, our system delivers the precision and flexibility you need to stay ahead.

Multi-Location Inventory Management

Coreware simplifies operations for businesses with multiple locations. It allows you to track inventory, sales, and employee performance across all stores from a single platform. Effortlessly transfer stock between locations, standardize pricing, and generate detailed reports to monitor overall business performance. Whether you’re scaling up or managing an established chain, Coreware keeps your operations seamless and connected.

Serialized and Lot-Tracked Items

Coreware ensures complete traceability for serialized and lot-tracked inventory. Each product can be individually identified and monitored throughout its lifecycle. This feature is ideal for businesses that require compliance or detailed tracking, such as those in regulated industries or handling high-value items.

Minimum and Maximum Stock Levels

Replenishment planning is effortless with Coreware’s ability to set minimum and maximum stock levels. You can configure reorder points for every product, ensuring automated purchase orders are generated when stock falls below the set threshold. This feature helps you maintain optimal stock levels while avoiding overstocking or shortages.

Kits and Bundles

Coreware supports the creation and management of product kits and bundles. This functionality is invaluable for retailers offering promotions or grouped items and for manufacturers bundling components into finished goods. The system tracks both the individual items and the kit as a whole, ensuring inventory accuracy at every step.

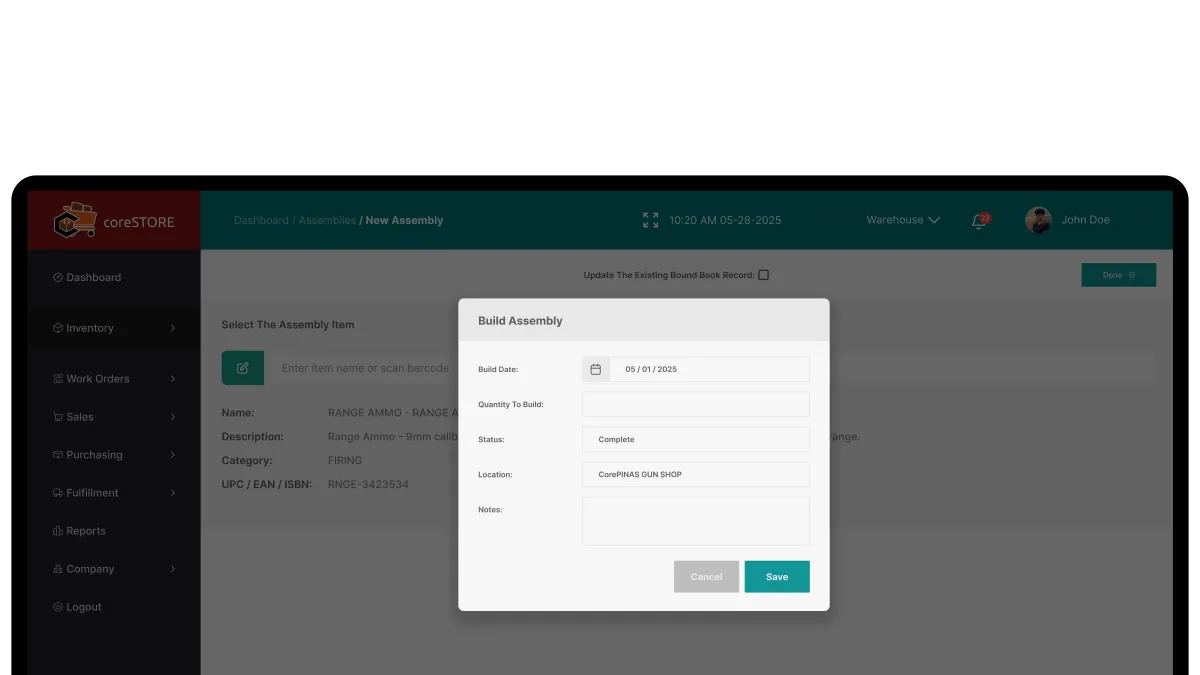

Assemblies and Cost Tracking

Manufacturers can take full advantage of Coreware’s support for assemblies and bill of materials (BOM). Track raw materials and finished goods while keeping a detailed record of associated costs. The system alerts you when raw materials run low, helping you avoid production delays and maintain accurate cost-of-goods data.

Variations and Item Matrix

Managing product variations—such as size, color, or material—is simplified with Coreware’s item matrix. This powerful tool allows you to handle multiple variations under a single product record, streamlining purchasing and inventory tracking. Whether you sell apparel, electronics, or custom products, Coreware makes managing variants seamless.

Unlimited Product Attributes

Every product is unique, and Coreware allows you to define unlimited attributes for each item in your catalog. From weight and dimensions to custom fields specific to your business, Coreware adapts to your needs, providing a fully customizable solution.

Barcode Label Printing

Printing barcode labels is a core feature of Coreware, designed to make organization and tracking effortless. Create and print fully customizable barcode labels for products, kits, and assemblies directly from the system. Whether you need shelf labels, price tags, or product-specific barcodes, Coreware supports it all.